Fatigue Risk Management in 24/7 Industries: What You Need to Know

Contrary to widely-held opinion, fatigue is not the same as feeling tired or drowsy. Fatigue scientists describe it as a state of impairment, compromising a person’s physical, mental, and emotional tolerances. On a worksite, fatigue affects a worker’s alertness and ability to perform even routine duties safely. And while fatigued workers increase the workplace’s risk and chance of incidents, they also impact productivity and the bottom line. In 2020, Ergonomic Trends reported that fatigued workers cost employers about $136 billion a year in health-related lost productivity.

Mitigating against fatigue is of high importance in 24/7 and mission-critical industries, but how can operations leaders effectively address it? The answer lies in fatigue risk management.

Fatigue risk management is a process of steps put into place to limit fatigue and fatigue-related risk. Implementation of a fatigue management strategy starts with baseline documentation and an assessment of where risk stems from and how it can snowball. Based on the information these evaluations provide, managers can make the necessary changes to mitigate fatigue-related risk and the impact of fatigue on their organization’s productivity.

To understand the real-world application of fatigue risk management, Shiftboard asked human factors specialist Mike Harnett, president of Solaris Fatigue Management, a simple question — “What are your strategies to manage fatigue?” Follow along as we share her guidance to one client’s metals smelting and refining facility and the implementation of a fatigue risk management system for their 24/7 operation.

Step 1: Establish a Baseline for Current Performance

Mike’s first step in creating a fatigue risk management strategy was to conduct initial research of the smelting facility (interviews, surveys, task analysis, and data review) to not only identify areas of risk but also establish an actual baseline for current performance and productivity. “You can’t make a successful plan if you don’t know where your needs and gaps are,” Harnett explains. “You can’t set goals or see how effective the plan is after implementation if you don’t document current productivity.”

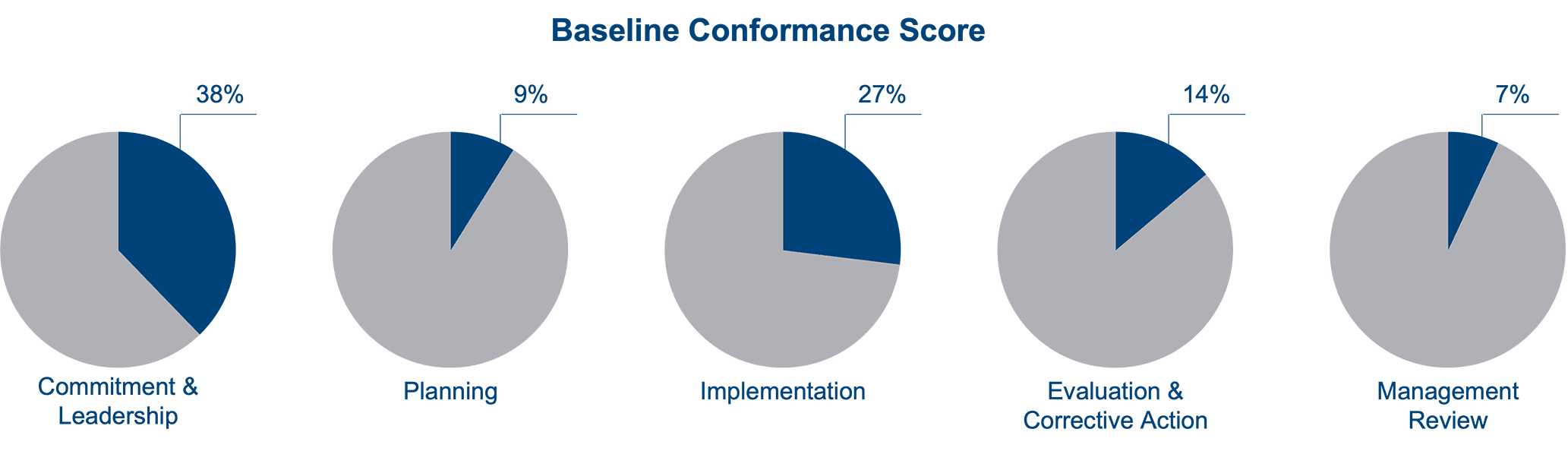

Achieving an accurate baseline requires management to take a hard look at current workforce management processes. Harnett asked a series of 135 questions to the metals smelting facility and then compared how their answers conformed to fatigue standards, including the API RP 755 guidelines. The guidelines recommended by API RP 755 apply to employees and contractors who perform process safety-sensitive actions during night shifts, rotating shifts, extended hours/days, or call-outs. They also apply to managers and supervisors who make process and safety-sensitive decisions.

The outcome of the assessment allowed managers a 10,000-foot view of the risks they needed to lighten and manage. Now they were able to identify targets and set objectives.

Step 2: Create a Plan to Align with Fatigue Risk Accumulation

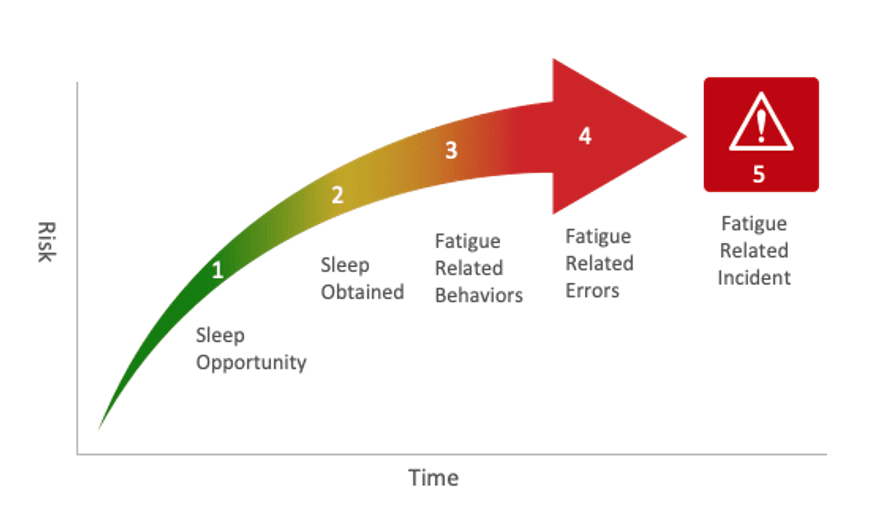

Having established a baseline performance score, Mike’s next step was to work with management to create a plan based off of a fatigue risk trajectory assessment. Fatigue risk management programs typically identify the program’s purpose, what it will look like, how it will be run, and how it will remain viable going forward. A fatigue risk assessment determines where fatigue risks are and how risk accumulates. It demonstrates how small factors lead to fatigue-related incidents by identifying four intervention points to mitigate fatigue.

Level One: Sleep Opportunity

A good schedule design considers many factors, including time of day, commutes, predictability, and essential activities of daily living (ADL). An employee needs time to complete their shift, commute, ADL, and still achieve seven to nine hours of sleep. Does their current schedule acknowledge these other tasks?

In the case of the smelting and refining facility, they assessed sleep opportunity by examining planned vs. actual hours, focusing on the number of hours worked and the number of consecutive shifts workers were accumulating. Long hours directly affect the turnaround time before an employee needs to show up for work again. Combined with commuting and ADL, fatigue science recommends a maximum of 12-hour shifts followed by 12-hours off. Paired with the Pipeline and Hazardous Materials Safety Administration’s (PHMSA) recommendation of a maximum of five consecutive shifts, scheduling can get complicated quickly.

It’s important to define rules that can be enforced but also establish processes for allowances. Exceptions happen; risk management policies help mitigate their occurrences and provide specific procedures when they do occur.

Mike Harnett, President, Solaris Fatigue Management

In Harnett’s case study, the company decided to set their normal schedules for 12 hours and allowed for a 14-hour maximum shift within 24 hours. Working beyond 14 hours required a documented risk assessment which included controls and justifications that must be forwarded to their area manager the next day. Working beyond 16 hours was permitted only for emergency work. Emergency work required managers to document a risk assessment, put appropriate controls in place, and gain immediate approval from the superintendent or manager. They also needed to guarantee a minimum of 10 hours off before allowing the employee to return to work. This rule may result in the worker not showing up for their regular shift at their normal time the next day, which provided another deterrent to scheduling unnecessary overtime. Having a documented risk assessment helped enforce the rules and created a paper trail for necessary exceptions.

Level Two: Sleep Obtained

While it is important to schedule employees to give them ample sleep opportunity, it’s also crucial to follow up on the number of hours of sleep actually obtained. When designing fatigue management strategies for mission-critical environments, the actual numbers become vital in mitigating risks. The facility sent out an employee survey to get this data and received responses from nearly 700 employees. The survey looked at factors affecting both sleep quantity and sleep quality. Findings from the survey quickly revealed that 81 percent of respondents were getting less than the minimum seven hours of sleep required, and 26 percent said they were getting less than five hours.

This data is concerning because sleep can affect alertness and the ability to respond to one’s environment, on top of being a general health risk. We learned that 57 percent of respondents showed up to work with fatigue that was the equivalent of .05 percent BAC impairment or higher on their very first night shift. While the first night shift is the worst for most shift workers, it is typical to rebound a bit on the second night shift.

Mike Harnett, President, Solaris Fatigue Management

Questions also screened for sleep disorders, as one in four people who have a sleep disorder don’t know that they have a sleep disorder. The survey further revealed that 45 percent of respondents identified moderate to high risk for obstructive sleep apnea, compared to the national average of 26 percent.

To address these issues, the company’s fatigue risk management strategy included awareness and lifestyle training. The company added sleep disorder screening into annual physicals and reviewed employee benefit plans to incorporate specific fatigue mitigation strategies such as light boxes, blackout curtains, and climate control for home use. Aiding your employees to manage less-than-ideal sleeping conditions can improve overall health and can boost their productivity when they have a shift.

Level Three: Fatigue-Related Behaviors

At this point in the fatigue risk trajectory, the fatigue exists, and it is the supervisor’s job to identify and mitigate the risk that comes with it. Findings from the survey highlighted a lack of tools or training for supervisors to identify and assess fatigue-related behaviors. Furthermore, they lacked guidance on what to do once fatigued employees were recognized.

The company revised their fatigue risk management strategy to incorporate a non-punitive fatigue reporting and a self-disclosure tool, trainings to identify fatigue-related behaviors, and procedures for individual and supervisor roles to follow to help control fatigue risk. On top of identification training, the company established separate policies for managing acute vs. chronically fatigued employees and provided mandatory alternative transportation home if employees worked 16 or more hours.

Level Four: Fatigue-Related Errors

This stage is the last opportunity to intervene before an incident occurs. Here, concern about fatigue-related errors rises. People who are fatigue-impaired will make mistakes. A common weak point for this organization was their shift handover process, where the quality of their information exchange was lacking. This ’Achilles heel’ resulted in unexpected challenges for the workers coming on shift. There were also no procedures for evaluating fatigue-related errors or near-miss scenarios.

To demonstrate to management how fatigue can translate into a near-miss or full-blown occurrence, Harnett evaluated a recent boom truck incident at their facility. The operator was attempting to load a shipping container onto the back of his boom truck. He was well experienced, but he didn’t measure the load and assess risks; instead, he took shortcuts and only secured the back outriggers. As he lifted and rotated the boom to the side of the truck, it overturned, and the boom tip crashed onto an adjacent structure. “We compared his performance against 26 indicators of impairment, and the following four really stood out,” explained Harnett. “He did not anticipate danger, he displayed decreased vigilance, he forgot elements of a task, and he displayed flawed logic.”

Level Five: Fatigue-Related Incident

At this point in the risk trajectory, an incident has occurred, but it is necessary to determine if it was fatigue-related or due to a different source of concern. Level five in a fatigue risk management system means an investigation is needed to identify critical fatigue-related factors. Let’s look at the boom operator incident again. This time, Harnett’s team asked science-based questions to evaluate the incident for possible fatigue factors. They discovered that the operator regularly worked up to 16 hours and had worked 17 shifts in a row before the incident. What’s more, he’d only slept 5 hours in the past 24 hours and had accumulated 14.5 hours of sleep debt in the previous 72 hours. The result of the investigation was that the boom operator was fatigued at the time of the incident and that fatigue contributed to the incident (which is important to distinguish as workers can be fatigued, but that doesn’t mean that was the reason an incident occurred).

Step 3: Manage Fatigue Proactively with Employee Scheduling Software

Today, organizations — especially those with 24/7 operations — should include automated scheduling solutions as part of their fatigue management strategies. Employee scheduling technology optimizes your schedule based on the context of your organization’s operational needs. In addition to assisting with schedule planning and day-of management, today’s intelligent technology manages the complexity of rules, regulations, and collective bargaining agreements that are unique to your worksite. Visibility into rule overrides, justifications, and work hours (broken down by level of organization or workgroup) gives supervisors the real-time data they need to make informed decisions on the front line. Configured employee scheduling technology with built-in compliance tools helps to predict and manage fatigue proactively, empowering employees at all job levels to prevent where possible, and mitigate where necessary, fatigue-related risk.

These materials were originally presented by Mike Harnett, president, Solaris Fatigue Management, and Sachin Agrawal, chief technology officer, Shiftboard, as part of the 2021 API Pipeline Control Room and Cybernetics Conference.

Frequently Asked Questions

-

What is fatigue risk management?

As per API RP 755 rules, a Fatigue Risk Management System (FRMS) refers to a comprehensive framework addressing the risks that may arise from fatigue. Designing an effective fatigue risk management strategy starts with baseline documentation and an assessment of where risk stems from and how it can accumulate. Based on these evaluations, managers can implement changes to mitigate fatigue-related risks and improve productivity.

Shiftboard has partnered with CIRCADIAN®, a leading research and consulting firm specializing in shiftwork and workforce performance, to provide 24×7 and mission-critical organizations with a comprehensive solution that not only optimizes their employee scheduling processes but also proactively manages fatigue risks. -

How does fatigue impact workplace safety and productivity?

Fatigue compromises a person’s physical, mental, and emotional tolerances, affecting their alertness and ability to perform even routine duties safely. Fatigued workers increase the risk of workplace incidents and negatively impact productivity, costing employers significant amounts in health-related lost productivity.

-

What are the benefits of employee scheduling software in managing fatigue?

Employee scheduling software helps manage fatigue proactively by optimizing schedules based on operational needs and ensuring compliance with rules, regulations, and collective bargaining agreements. This technology provides visibility into rule overrides, justifications, and work hours, allowing supervisors to make informed decisions to prevent and mitigate fatigue-related risks.

-

How can sleep opportunity be optimized to manage fatigue?

Sleep opportunity can be optimized by designing work schedules that consider factors such as time of day, commutes, predictability, and essential activities of daily living (ADL). Schedules should allow employees enough time to complete their shifts, commute, perform ADLs, and still achieve seven to nine hours of sleep.

-

What strategies can be used to manage fatigue proactively?

Proactive fatigue management strategies include conducting baseline performance assessments, creating fatigue risk management plans, optimizing sleep opportunities, monitoring sleep obtained, identifying fatigue-related behaviors, and addressing fatigue-related errors before incidents occur.

-

Why is real-time data important in managing fatigue risk?

Real-time data is crucial in managing fatigue risk as it provides supervisors with immediate insights into work hours, rule overrides, and justifications. This information allows for informed decision-making on the front line, helping to prevent and mitigate fatigue-related risks effectively.

-

What are your strategies to manage fatigue?

Effective strategies to manage fatigue include conducting comprehensive assessments, implementing fatigue risk management plans, optimizing work schedules, promoting sleep hygiene, providing training for supervisors to identify fatigue-related behaviors, and using employee scheduling software to proactively manage and monitor fatigue-related risks.